Nickel Electroplating

Nickel plating provides high ductility, corrosion resistance, and hardness. It can also improve brightness and external appearance of part. Different chemicals incorporated into the process deliver anything from Bright Nickel, Satin Nickel, Sulfamate Nickel, Black Nickel and Electroless Nickel.

Zinc Electroplating

Zinc is a metal with high corrosion resistance. The coating prevents oxidation of metal by forming a barrier and by acting as a sacrificial anode if this barrier is damaged. Zinc plating is one of the most popular anti-rusting methods. Cost is low but effective. We supply color in white, blue, black, yellow and rainbow.

Gold Electroplating

Gold is a precious metal with excellence conductivity, solderability and resistance to corrosion. It also gives precious appearance to part by plating. Out terminal, contact plate and cosmetic product is often gold plating. Either barrel and rack plating can be provided by specific design need. We can also achieve different plating thickness upon requirement.

Spray / Power Painting

It is a process to spray liquid paint / powder onto a surface through gas pressure. We offer wide range of colors and texture, upon customer’s requirement. Thickness requirement is also strictly controlled, in order to deliver excellent product.

PVD

PVD is vacuum deposition method to creates coating with superior hardness and resistance to abrasion and corrosion. This technology is applied as purpose of decorative and mechanical property is excellent, market demand is continuously increasing.

Hairline / Polish / Sandblast

These are texture forming process, before or after finishing process. For some parts, these processes are necessary to achieve handfeel and cosmetic appearance, which could be the most important requirement for some consumer goods.

Anodizing

Anodizing is an electrolytic process that creates a protective oxide layer on aluminum material . Purpose is to increases resistance to corrosion and wear. Different color is also created by the chemical reaction. This finishing is widely applied on consumer goods, cosmetic cases, construction material and window frames. We supply color options such as silver, black , blue, red, gold and rose gold etc.

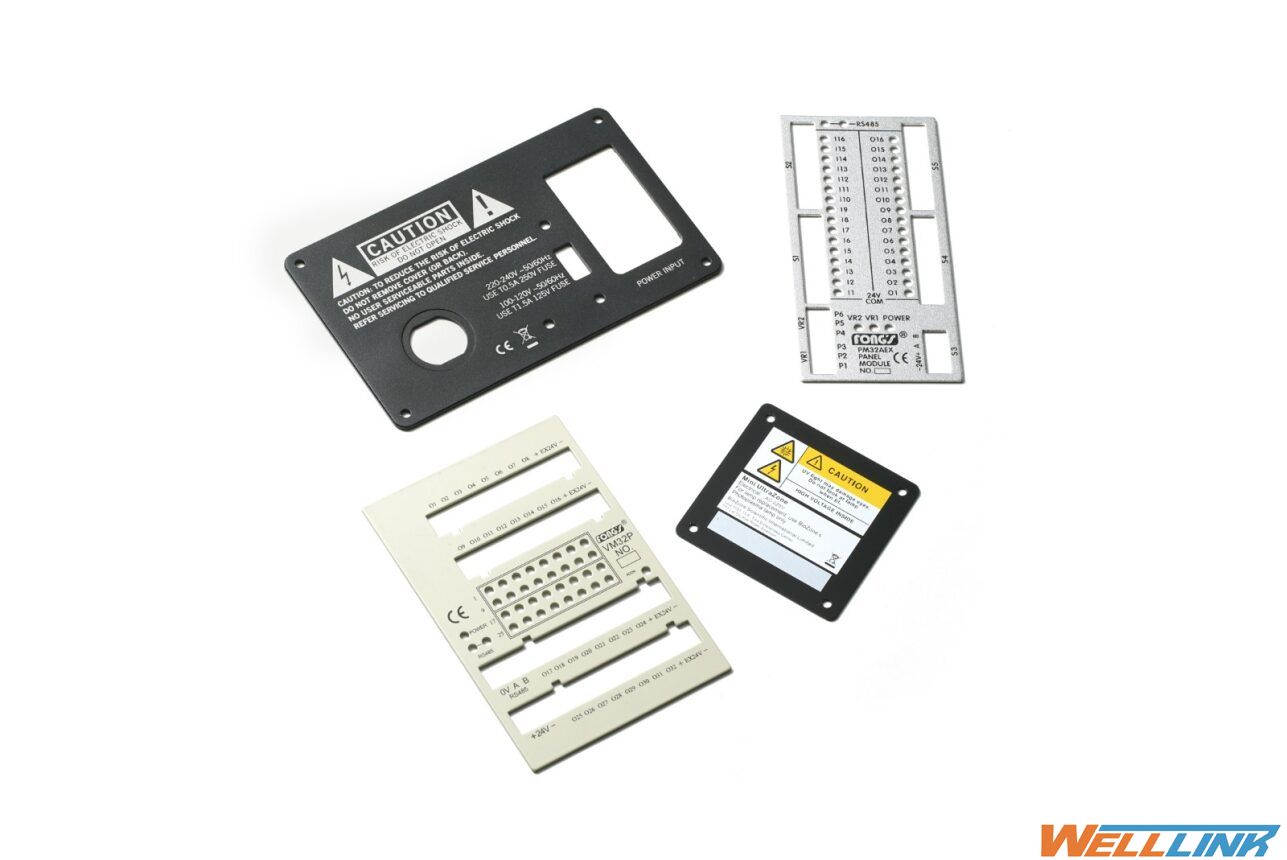

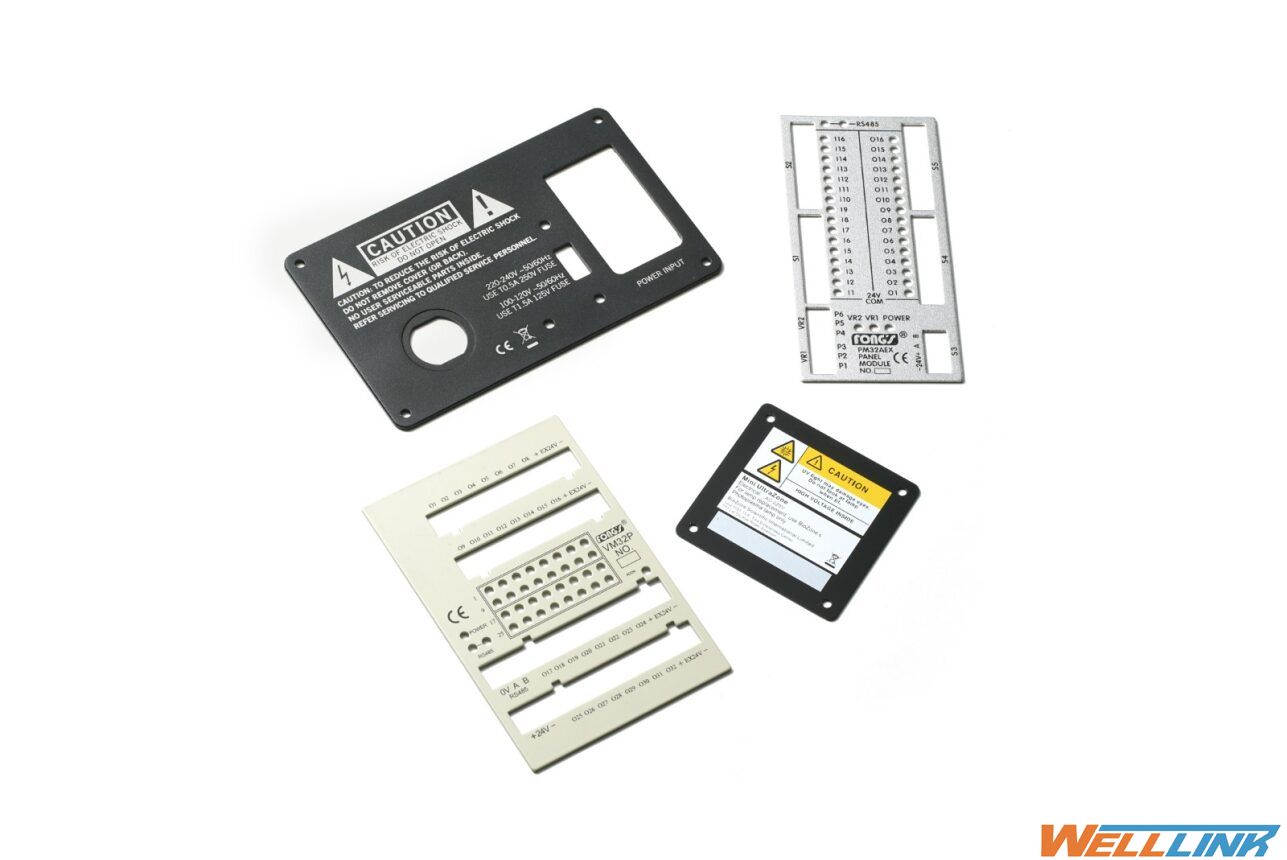

Screen Printing

These are texture forming process, before or after finishing process. For some parts, these processes are necessary to achieve handfeel and cosmetic appearance, which could be the most important requirement for some consumer goods.